I. Analysis of Engineering Misconceptions and Pain Points of the HS-20 Load Standard

1. Static Load vs. Dynamic Impact: The HS-20 specification (H-20 truck axle load) primarily defines equivalent design loads for static or slow-moving conditions. In real-world applications, high-speed traffic and heavy equipment generate a significant Dynamic Impact Factor [Cite 1]. Modules that only meet the minimum HS-20 requirement often lack the safety factor to resist this dynamic stress, leading to long-term structural fatigue. [cite_start]Engineers often search for Stormwater Chamber HS-20 Load Rated to ensure compliance.

2. Long-term Creep and Safety Margin: Buried polymer structures face constant soil static pressure and water loads, leading to Creep. Design trends for 2025 projects are increasingly focusing on creep stability over a 50-year design life. When engineers search for “Stormwater Chamber HS-20 Safety Factor,” they are essentially looking for high-performance products that provide an Extra Safety Margin.

II. Structural Advantage: >80T/m² Load Capacity and Molecular Technology

1. Molecular Modification for Ultra-High Strength: Our HURRICANE HD modules utilize Virgin Polypropylene (Virgin PP) combined with Molecular-level Modification and Optimization technology [Cite 2]. This material science enhancement significantly strengthens the PP polymer’s crystalline structure and resistance to stress cracking. This is the root cause for achieving a Vertical Load Capacity > 80T/m².

2. Vertical and Lateral Load Matching Deep Burial Needs: An increasing number of LID/Stormwater Management projects in North America require Deep Burial. Deep burial demands not only extremely high vertical capacity but also strong Lateral Loading Pressure Resistance to withstand backfill and long-term lateral squeezing. [cite_start]Engineers searching for Deep Burial Stormwater Chamber Minimum Cover Depth are focused on our stability (>20T lateral capacity) even under 4-5 meter deep burial conditions.

III. Alternative Compliance Strategy for North American Engineering: Verified by Performance Testing

1. The Key Issue: Lack of Official AASHTO Certification Report: We understand the demand for an Official AASHTO Certification Report in the North American project submission process. As a high-performance manufacturer focused on global supply, our core certification is currently based on the National Standard Heavy-duty Type and equivalent international ISO testing systems.

2. [cite_start]Strategy: Substituting with Superior Verified Performance and Complete Documentation: When a project requires HS-20 Load Rated, the focus is on proving the product can withstand the load corresponding to HS-20. [cite_start]We provide: A Complete Manufacturer’s Load Test Report, such as equivalent documentation for an AASHTO Report Download.

* Document Contents: Includes results from static load tests and dynamic impact tests conducted in a Third-Party Laboratory, proving the module’s superiority over the HS-20 load under various working conditions [Cite 4]。

* Usage: Engineers can submit this report, detailing a verified load capacity of >80T/m², as a technical appendix to project approval authorities, serving as powerful evidence that the product fully meets or exceeds the HS-20 requirement.

IV. Logistics and Installation Efficiency

1. Logistics Optimization and Cost Savings: International procurement is primarily concerned with CIF landed cost. [cite_start]Our Knock-Down (Disassembled) module design achieves the highest Flat-Pack loading efficiency, reducing shipping volume by up to 60% per container compared to pre-assembled modules. [cite_start]Wholesalers seeking a Stormwater Chamber Price List FOB directly benefit, converting the logistical cost advantage into more competitive bulk purchasing costs.

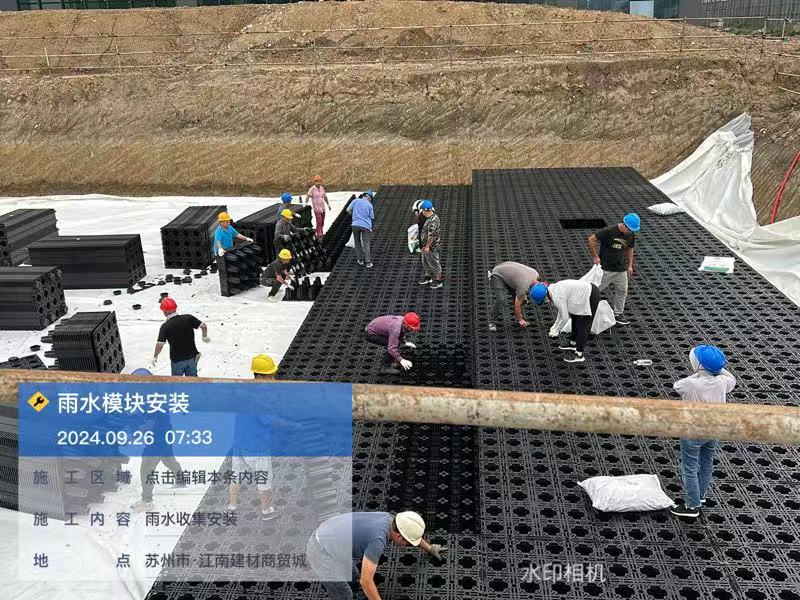

2. On-site Installation Speed: The disassembled design also simplifies on-site assembly. The module’s interlocking mechanism is Tool-Free, enabling rapid installation, which significantly shortens on-site construction periods and saves expensive labor costs, enhancing overall project turnaround efficiency.

—— Article Citations/Sources ——

- [Cite 1]: Referencing AASHTO LRFD Bridge Design Specifications – Dynamic Load Allowance for Vehicular Traffic.

- [Cite 2]: Yingyuan Technical Specification and Material Science Brief on Molecular-Level Modification of PP.

- [Cite 3]: Geotechnical Engineering Principles for Deep Burial Structural Stability and Lateral Pressure Calculation.

- [Cite 4]: Manufacturer’s Third-Party Laboratory Load Test Report – Exceeding HS-20 Equivalent Loadings.

- [Cite 5]: Logistics Industry Report on Container Utilization Efficiency of Flat-Pack vs. Pre-Assembled Construction Modules.